Dosing pumps and Feeding pumps are oscillating displacement pumps for the dosing and feeding of liquids in all industrial fields. We can dose nearly all flowing media, even with aggressive, abrasive, odorous, radioactive, inflammable, viscous or toxic properties – reliably and safely!

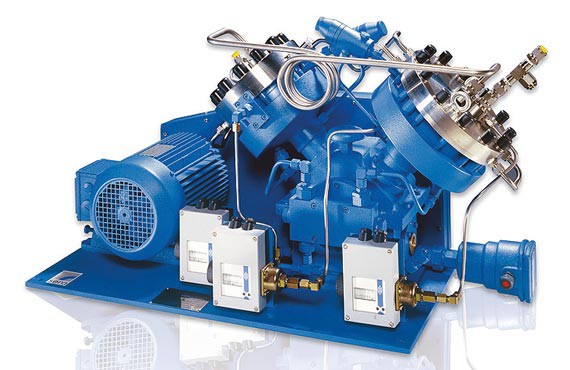

With Piston Compressors relatively large amounts of gas can be conveyed at low suction pressures. The piston compressor series can be used wherever production processes require large quantities of absolutely oil-free gas. So we can react flexibly to virtually all customer needs.

Some Application fields:

The series of the Piston Compressors KV1, KV2 and KV3 is characterized by the vertical design and the piston compressors are air-cooled.

The series of Piston Compressors KV4, KV5, KV6, KV7 and KV8 is characterized by a vertical design and the piston compressors are water-cooled.

The series of the Piston Compressors KV9 is characterized by a V-construction and is water-cooled.

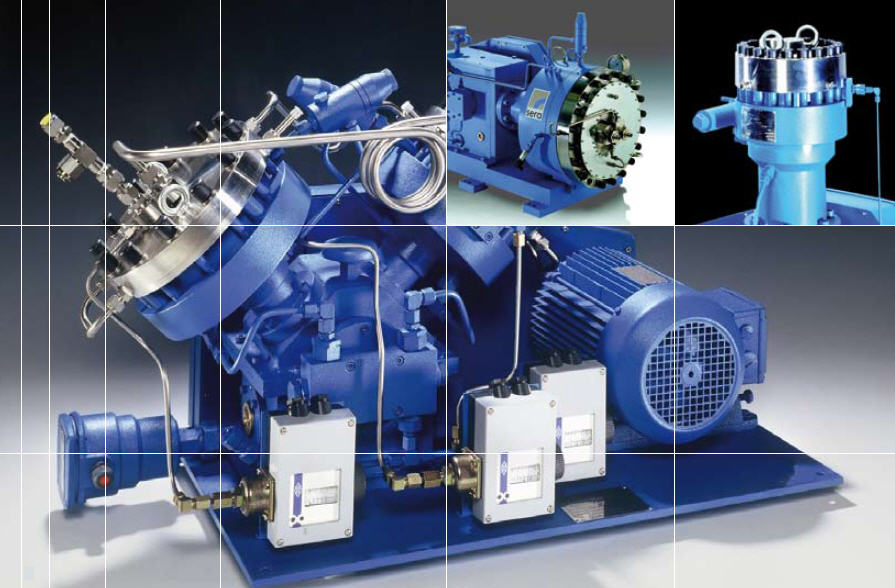

Metal Diaphragm Compressors of the series MV with hydraulically coupled PTFE-diaphragms.

Performance of the type series MV 1 … up to MV 4 …(upright)

Metal Diaphragm Compressors of the series MV with hydraulically coupled PTFE-diaphragms

Performance of MV5 horizontal:

Metal Diaphragm Compressors of the series MV with hydraulically coupled PTFE-diaphragms

Performance of MV5 II – horizontal:

S-Series –

The Screw: dry running and low maintenance vacuum pump

The S-VSI screw vacuum pump (sizes 100 and 300) represents modern, state-of-the-art dry running technology that excels when it comes to small carbon footprint and low life cycle costs. It is used in a variety of industrial applications such as drying and packaging. Click here to find out more.

The S-VSA and S-VSB dry running, contact-free screw vacuum pumps are primarily used in the chemical and pharmaceutical industries for processing applications. A contamination with oil or other operating liquids is impossible. Several pump sizes are available with ATEX certification.

Advantages at a glance

C-Series –

Innovative Claw Technology

The C-Series claw pumps and compressors of Elmo Rietschle generate contact-free vacuum or compressed air efficiently and economically. This is possible because of the principle of internal compression. The gas is pre-compressed within the compressing chamber and is then discharged.

This leads to an evident energy saving compared to rotary lobe blower designs without internal compression.

Advantages at a glance

R-Series –

Rotary Lobe Blowers: rugged and economical

These compact rotary lobe blowers belong to the group of dry running positive displacement pumps. This means that there is no need for oil or grease in the compression chamber. Only gear box and bearings, which are separated from the pumping chamber, are oil lubricated. Two non contacting triple lobed rotary lobe rotors rotate against each other in the compression room.

The triple lobed rotors avoid pulsation problems. The blowers are customized to cater for the varying demands of our customers‘ applications.

Advantages at a glance

V-Series –

Dry Running and Oil Lubricated Rotary Vane Pumps and Compressors

Elmo Rietschle offers dry running and oil lubricated rotary vane pumps which cover a wide performance range.

The eco-friendly dry running rotary vane pumps are used for vacuum, pressure and combined pressure and vacuum applications. The time-tested oil lubricated rotary vane machines are typically used for generating vacuum.

Advantages at a glance

L-Series –

Compact Liquid Ring Pumps for Heavy Duty

Extreme conditions, which prevail in humid and wet processes, lead to lime scale or abrasion, and hence to a considerable reduction in the performance of the pump. Elmo Rietschle liquid ring pumps, however, meet these challenges.

The use of high-quality materials such as stainless steel and ceramics ensure utmost reliability and constant operating characteristics – for years to come.

Advantages at a glance

G-Series –

Side Channel Blowers Leading in Excellence

Some technologies are so good that it is hard to improve them. Side channel blowers from Elmo Rietschle are such an example. They have proven their reliability in service for many decades, performing flawlessly day in and day out with virtually no down time. Noise levels have been lower than that of most other vacuum pumps and compressors.

Side channel blowers are used for conveying gases and gas-air mixtures.

Advantages at a glance

F-Series –

Centrifugal blowers for industrial use

Elmo Rietschle offers a broad portfolio of single and multistage centrifugal blowers for vacuum and pressure operation.

The applications of Radial blowers are mainly used in the packaging and paper industries, with the smaller units are suitable for extracting dust with fine material such as paper powder and powdered solids.

Benefits at a glance