Hapa is Swiss quality. All of our printing system solutions are developed and produced at our headquarters near Zurich, Switzerland. A worldwide network of sales and service centers provides customers with professional, local support.

Hapa is a proud member of Coesia Group, a group of innovation-based industrial solutions companies operating globally, and headquartered in Bologna, Italy.

Our expert teams offer you full services, engineered to succeed:

Research and development

Design and production

Sales and project management

Aftermarket services

Inks developed individually by Hapa Ink

http://www.hapa.ch/

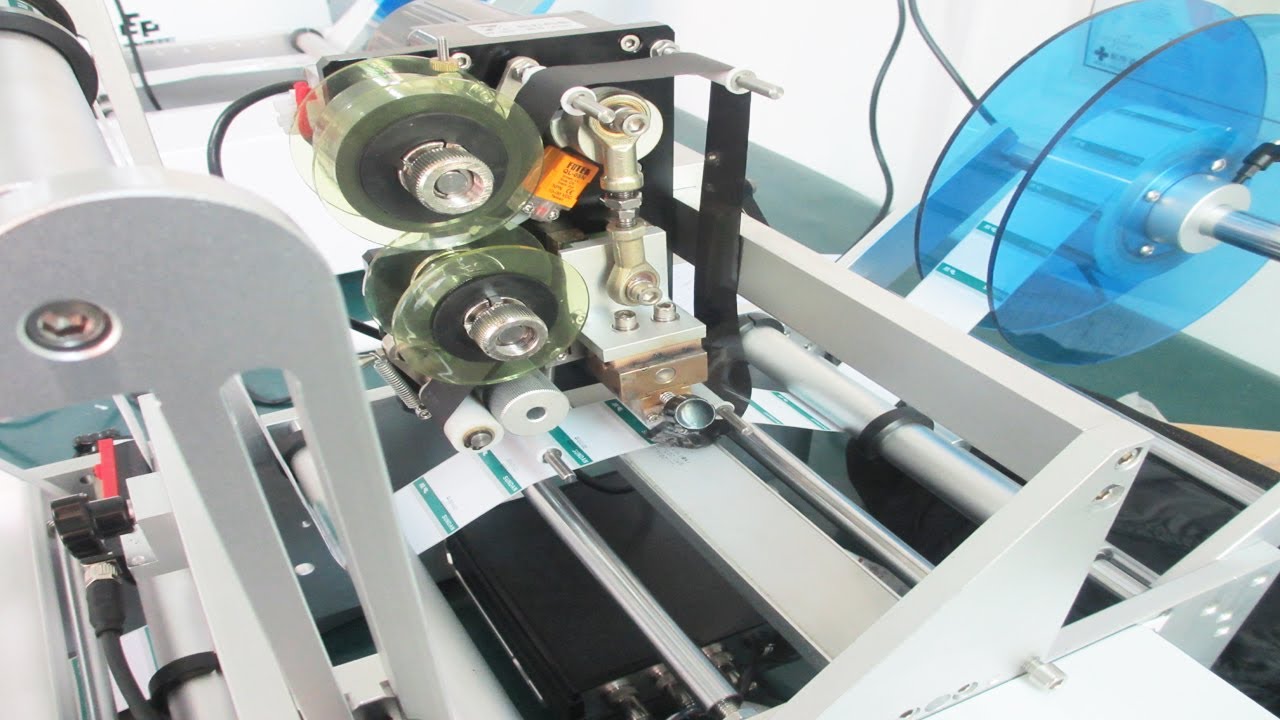

Sorting machine for full automatically sorting of pharmaceutical- and confectionery products.

Product sorting regarding diameter, length and thickness.

Inspection is performed concerning particulate impurities of the content and defects of the container and the closure.

Inspection machine for visual inspection of ampoules, carpoules, vials, infusion bottles, syringes.

Inspection belt for visual inspection of tablets, dragees and capsules. Tablet turning belt for visual inspection of tablets and dragees.

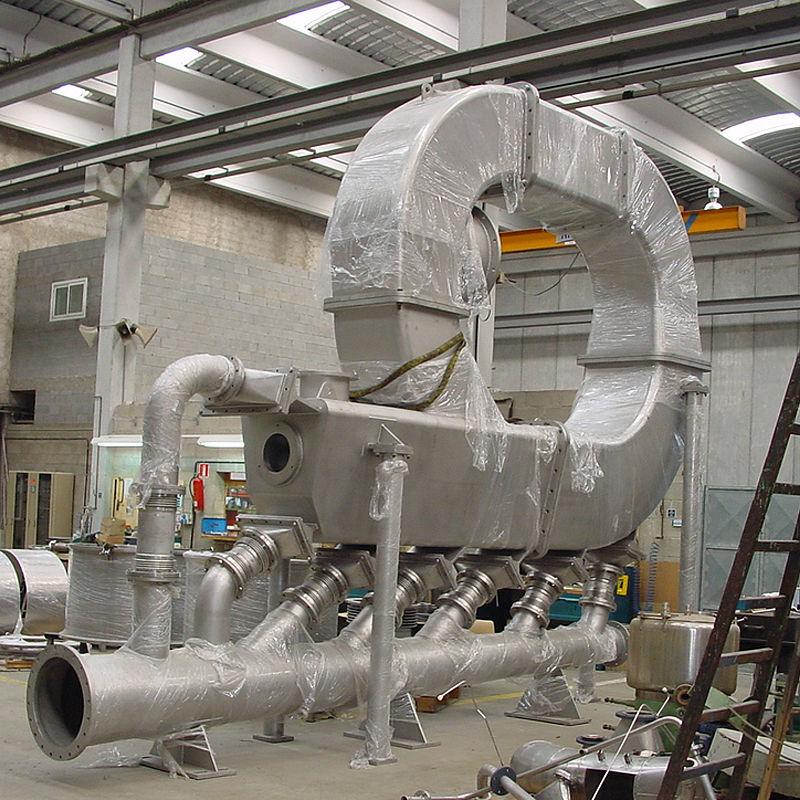

Reverse Osmosis is a high pressure separation process to remove low molecular solutes (salts, small organics molecules) from a solvent (water). The separation occurs with an imposed pressure higher than the osmotic pressure, forcing the solvent to pass through the membrane while the solute is rejected, monovalent ions included. Operating pressure are required in the range up to 100-120 bar.

Reverse Osmosis is a high pressure separation process to remove low molecular solutes (salts, small organics molecules) from a solvent (water). The separation occurs with an imposed pressure higher than the osmotic pressure, forcing the solvent to pass through the membrane while the solute is rejected, monovalent ions included. Operating pressure are required in the range up to 100-120 bar.

UF is a low pressure process for selective filtration of molecules of specified size and weight. Material ranging in size from 1000 MW to 1.000.000 MW are retained by UF membrane while lower molecular weight compounds, salts and water are passing through. Typical applications of UF membrane are concentration and recovery of high molecular weight compounds separation/removal of contaminants, clarification, removal of colloids and suspended solids, thus being used as pretreatment for reverse osmosis units.

Microfiltration is the most open cross-flow filtration device. Typical application of this low pressure process is the removal of high molecular weight compounds such as bacteria, fats, yeasts and fungi: clarification of chemical, biological, pharmaceutical or food solutions, product purification, waste water treatment.

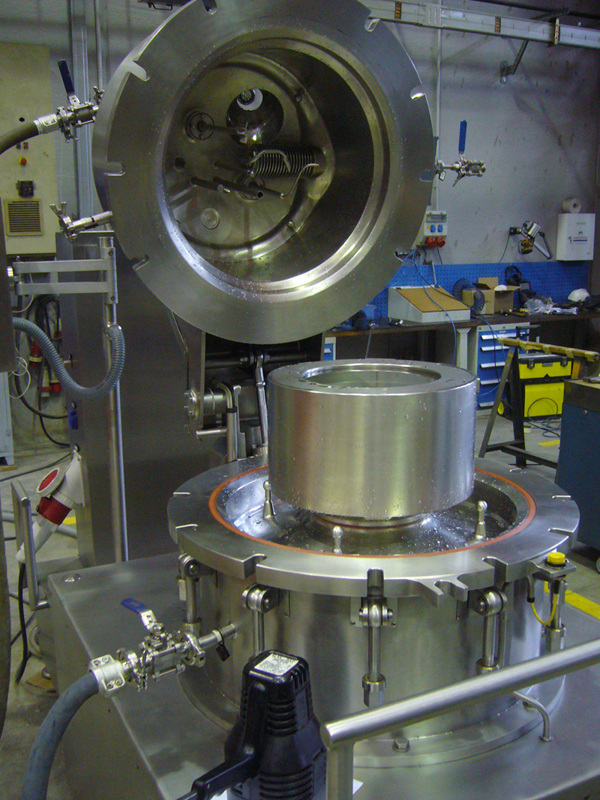

The basic idea for our InLine Homogenizer is to extend the proven principle of the rotor-stator system for versatility applications.

Its newly developed design differentiates the zoatec InLine Homogenizer Typ IL from all other conventional designs.

Aliquam lorem ante, dapibus in, viverra quis, feugiat a, tellus. Ut varius tincidunt libero. Curabitur at lacus ac velit ornare lobortis. Cras sagittis. Duis leo.

Nullam quis ante. Sed augue ipsum, egestas nec, vestibulum et, malesuada adipiscing, dui. Aliquam eu nunc. Aenean commodo ligula eget dolor. Vestibulum purus quam, scelerisque ut, mollis sed, nonummy id, metus.

Praesent vestibulum dapibus nibh. Sed lectus. Sed a libero. Curabitur ullamcorper ultricies nisi. In consectetuer turpis ut velit. In auctor lobortis lacus. Proin magna. Quisque malesuada placerat nisl. Morbi mollis tellus ac sapien. Praesent ac massa at ligula laoreet iaculis.

Automatic machine for the production of suppositories in cavities made of aluminium or thermoforming plastic.

Although the ability to develop advanced machine technologies is crucial, Romaco Macofar is convinced that flexibility and ease of validation are also essential criteria for meeting the specific requirements of customers in the pharmaceutical and cosmetics industries. For many years now, Romaco Macofar has enjoyed an excellent reputation as a global supplier of filling solutions for sterile powders and granules.

Working in close partnership with its customers, Romaco Unipac successfully meets the demanding requirements of today’s market with machines that are optimally adapted to user needs. With significant success – 1200 dedicated solutions for filling pharmaceuticals and cosmetics into tubes have been designed and installed to date.

With numerous innovations and advanced technologies, Romaco Promatic has evolved into a globally recognised brand. Customers in the pharmaceutical, cosmetics and food industries trust in the groundbreaking cartoning solutions, rich know-how and excellent customer service of Romaco Promatic

The Noack brand has established Romaco internationally as a supplier of choice when it comes to robust, flexible blister solutions for small to medium batch sizes. Contract packaging companies and generics manufacturers particularly appreciate the short retooling times that speed up product changeovers as well as the high level of reliability and availability.

Romaco Kilian enjoys a global reputation as a supplier of efficient and user friendly tableting machines for use in the pharmaceutical, cosmetics, food and chemical industries. For several decades now, customers all over the world have particularly valued our excellent customer service and our fast response and delivery times. Numerous patents testify to Romaco Kilian’s longstanding commitment to the development of solutions and applications tailored to user needs.